How to Use Your U-Coat Epoxy Flake Kit to transform your space

Our epoxy kits are simple to use and deliver professional results—just make sure you carefully follow each step. We recommend watching our video tutorial on YouTube before starting, and remember, we’re always available by phone, email, or social media if you need help.

1. Preparation

- Works on stone, wood, laminate, and concrete (see Concrete Suitability below).

- Degrease the area, wipe clean, and sand with 80-grit paper (round off sharp edges).

- Fill joins with a 2-part filler, sand flat, then rinse with water and dry.

- Wipe down with isopropyl alcohol and cloth (included in kit).

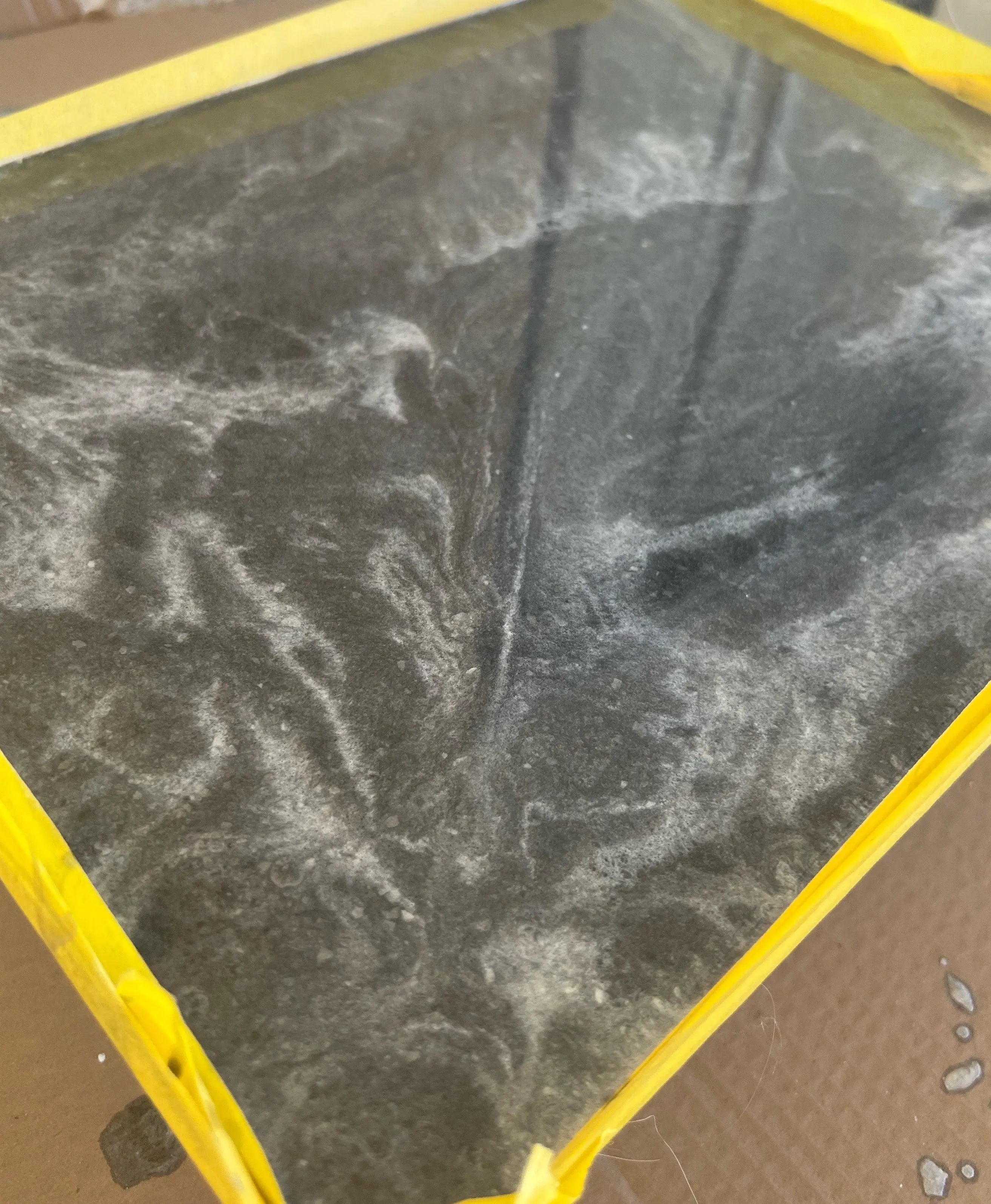

Concrete Suitability

- Ensure no old coatings, sealers, or flaky paint remain.

- Test porosity: water should soak into the slab, not bead.

- If water beads, grind with a concrete grinder.

- Check for efflorescence (white powdery residue) or rising damp—resolve before coating.

- Clean thoroughly with U-Coat Degreaser, Conetch solution, and a high-pressure cleaner.

- Allow at least 6 hours drying time before coating.

2. Masking

- Carefully tape off all surrounding areas and cover with plastic.

- Build a masking tape barrier (about 2 cm high) along edges to stop epoxy running off. For strength, reinforce with Gorilla Tape.

3. Mixing

- Mix metallic powder into Part A using a drill.

- Add Part B to Part A and mix for 5 minutes.

- Split into smaller buckets and add small amounts of spray paint colour (non-waterbased).

- Rough mix with a stir stick.

4. Application

First Coat (Epoxy Primer)

- Mix “Coat 1 Part A” + “Part B” thoroughly (5 mins).

- Cut in edges with brush, roll out in sections, and back-roll for even coverage.

- Allow 7 hours (or until touch dry) before proceeding.

Second Coat (Epoxy + Flakes)

- Mix “Coat 2 Part A” + “Part B” (5 mins).

- Apply in sections as before.

- While still wet, scatter flakes evenly (“feed the chickens” motion).

- Let dry for at least 7 hours.

Third Coat (Urethane Finish)

- Mix “Coat 3 Part A” + “Part B” (5 mins).

- Optionally add glitter or slip-resistant additive.

- Cut in edges, roll out evenly, and back-roll.

- Coat will look milky but dries clear.

5. Final Steps

- After 1.5 hours, carefully remove tape on edges, sinks, and cooktops.

- Rub epoxy over edges to help it flow. Clean drips with alcohol and cloth.

- Once cured, scrape any hardened drips with a metal scraper.

- Remove all masking and plastic before epoxy fully hardens.

6. Curing & Care

- Allow 24 hours before foot traffic, 7 days before vehicle traffic.

- Avoid direct sunlight over 30°C or rain within 24 hours of application.

- Don’t drag heavy objects; clean only with mild detergent.